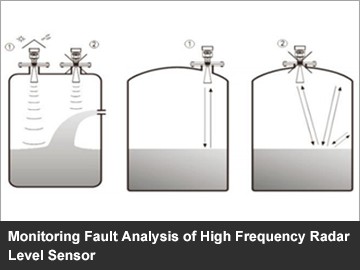

Monitoring Fault Analysis of High Frequency Radar Level Sensor

More and more users are using high frequency radar level sensors to monitor the liquid level. However, during the actual measurement process, the radar liquid level sensor may not be detected. In order to solve the monitoring fault of the wireless sensor, I will give you a simple analysis from the practical application of the radar sensor.

High frequency radar level sensor for monitoring tank level

When the high frequency radar level sensor is used to monitor the benzene tank level, it will crystallize. Because benzene crystallizes at temperatures below 6 degrees Celsius, it is actually frozen. At the same time, benzene is a kind of easily volatile liquid. In order to prevent benzene from freezing in winter, the process is designed with loop steam heating on the storage tank, which causes benzene to volatilize in the storage tank in winter. The radar level sensor has no heat and heat treatment measures, and is sometimes installed on the nozzle at the top of the tube. The temperature is much lower than the temperature inside the tank. In winter, the benzene vapor hits the antenna of the level gauge. The condensation junction eventually freezes, affecting the use of the radar level gauge. Most users take the approach of removing the meter and cleaning the antenna. After doing this kind of work, the problem is usually eliminated. Therefore, I would like to remind everyone that if it is a problem in winter, first consider the treatment measures of heat preservation and heat tracing.

The solution of HF radar liquid level sensor

In order to solve this problem fundamentally, it is recommended to consider another type of radar level sensor. If you want to measure the condensation phenomenon, you can use the high-frequency radar level sensor with a purging device, so that the wind can be blown directly from the inside of the transmitting antenna, or the plastic cloth can be sealed with a transparent plastic cloth at the bell mouth to reduce the crystallization at the antenna, thereby reducing maintenance frequency.