Differential Pressure Sensor for Leakage Detection

One of the most commonly used industrial pressure measuring instrument is differential pressure sensor, which is generally applied in petrochemical industry, food, papermaking, machinery, pharmacy, aviation and etc.

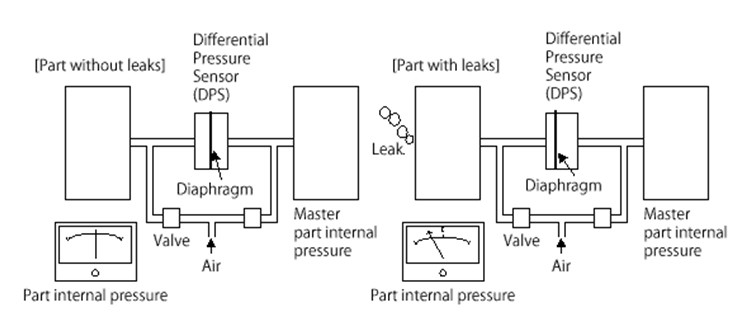

Application of Differential Pressure Sensor in Leakage Detection System

The working principle of a differential pressure sensor is that it senses the difference in pressure between two ports on a device and produce an output signal. In industrial application, it is mostly used to detect the leakage. The leak detection system generally uses them to calculate the leak rate to determine the sealing integrity of components or if the pipelines are blocked. And gas engines can be tested to determine whether their sealing is airtight, or high-pressure process pipelines in use can be monitored to detect leaks.

How to Install Differential Pressure Sensor

Unlike other pressure sensors, differential pressure sensors are typically packaged with two ports to which pipes can be attached. The pipes are then connected to the system where the measurement is to be made. And generally, the sensors are generally installed at the bottom place outside a tank.

Related Posts

1. Troubleshooting of Differential Pressure Transmitters

2. Maintenance Notices of Differential Pressure Transmitters

3. How Differential Pressure Transducers Used in Filter Monitoring?

4. TOP 10 Differential Pressure Transmitter Manufacturers

5. The working principle of differential pressure transmitter