Exploring Ultrasonic Blind Area in Ultrasonic Level Transmitters

Ultrasonic liquid level sensor users are well-acquainted with the existence of blind zones inherent in these devices. But what exactly constitutes the blind zone of an ultrasonic level sensor, and what factors influence it?

What is the Ultrasonic Level Sensor Blind Area

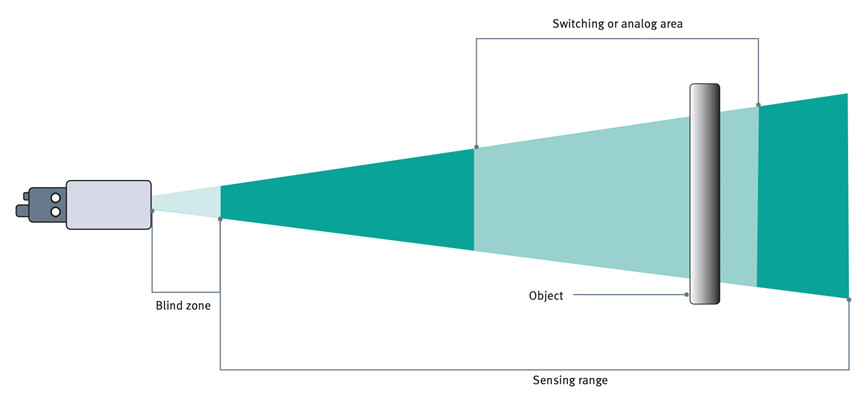

Comparable to the blind spot in human vision, the blind area of an ultrasonic water level sensor represents an area where the emitted ultrasonic pulses cannot simultaneously detect reflected echoes. This limitation arises from the specific time width of the emitted pulses, coupled with the ongoing vibrations of the sensor post-emission. The consequence is a small, immeasurable distance from the probe’s surface downward, known as the blind zone.

Factors Impacting Ultrasonic Level Meter Blind Zones

a. Working Principle: The blind zone is intricately linked to the working principle of the ultrasonic level meter. When encountering a measurement blind zone, pulse signals fail to reach that particular area.

b. Measurement Range: The blind zone correlates with the measurement range of the device. In industrial settings, regardless of the brand, ultrasonic level meters typically exhibit blind zones ranging between 300-500mm. Generally, devices with smaller measurement ranges tend to have smaller blind zones, while those with larger ranges often have correspondingly larger blind zones.

How to Deal With Ultrasonic Measurement Blind Zones

1.When aiming for precise measurements, it is crucial to consider the blind zone when determining the installation position of the device. Adequate margin and careful consideration of the transducer probe’s height during installation are essential for ensuring accurate level monitoring and safe instrument usage.

2.In situations where minimizing the blind zone is a priority, users can select ultrasonic level meters with smaller blind zones, typically ranging from 400-600mm. However, it’s important to note that devices with smaller blind zones often come with relatively smaller measurement ranges, usually around 600mm.

3.In the presence of foam, particles, or other substances on the liquid surface, measures can be implemented to ensure that ultrasonic waves are not excessively disturbed during propagation. Regular maintenance and calibration are essential to reduce blind zone issues stemming from equipment aging or errors.

4. Or you can directly consider Holykell upgraded UE3003 ultrasonic level sensor.

Introducing Holykell’s Enhanced Ultrasonic Level Sensor: Redefining Precision in Measurement

The ultrasonic level sensor UE3003 incorporates the latest algorithm and ultrasonic technology.

Advantages of the Upgraded Ultrasonic Level Sensor:

Smaller Blind Area: It boasts a remarkably reduced blind area of only 150mm, enhancing its capability to accurately measure levels even in confined spaces or near obstructions. This improvement is particularly beneficial in applications where space constraints are critical.

Enhanced Precision: With a smaller blind area, our ultrasonic level sensor delivers high precision up to 0.25%F.S in measuring liquid levels. This is especially crucial in industries where precise measurements are essential for efficient operations and compliance with safety standards.

Versatility: its wide measurement ranges from 2.5m to 10m, expands its range of applications across various industries, including manufacturing, water treatment, and chemical processing, and suitable for both small and huge tanks. Its versatility makes it an ideal choice for a wide array of liquid level monitoring needs.

Increased Reliability: Holykell’s commitment to quality ensures that our ultrasonic level sensor not only meets but exceeds industry standards. The reduced blind area contributes to the overall reliability of the sensor, providing users with confidence in their monitoring and control systems.

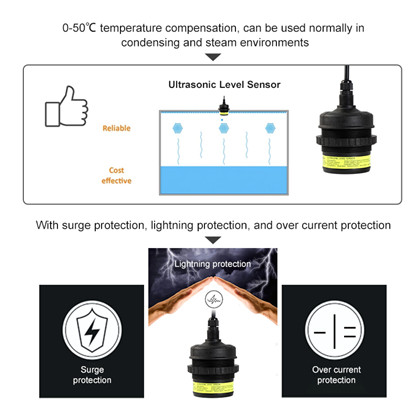

Improved Safety and durablity: To make it durable and stable in outdoor applications, even in harsh environments, we add or enhance the protection:

●Reverse polarity protection

●Surge lightning protection

●Anti-obstacle interference

●Power-off self-recovery

●IP67-IP68 rating

Why We Make this Upgrade?

At Holykell, we are committed to pushing the boundaries of innovation, and our latest upgrade to the ultrasonic level sensor is a testament to that dedication. We are excited to announce a breakthrough enhancement that significantly reduces the blind area, setting a new standard in precision and reliability.

Our decision to upgrade the ultrasonic level sensor stems from a relentless pursuit of excellence. Recognizing the evolving needs of industries, we aimed to address a common challenge faced by traditional sensors – the blind area. By shrinking the blind area, we’ve effectively increased the accuracy of our sensor, providing users with more precise and reliable measurements.

Innovation is at the core of Holykell, and our upgraded ultrasonic level sensor underscores our dedication to delivering cutting-edge solutions that empower industries to thrive. Upgrade your monitoring capabilities today!

FAQs

1. What’s the Difference Between Ultrasonic Level Sensor and Radar Level Sensor

2. How Ultrasonic Level Sensors Used in Complex Environment