Why do we choose interface level transmitter to monitor industrial tank?

Most people are willing to use interface level transmitters to monitor the level of industrial tanks. But there are still a few engineers and purchasing agents have been not understand the purpose of the interface level transmitter and reason, in their opinion, in order to achieve the purpose of industrial tank level monitoring, industrial sensors, high cost performance and durability is the focal point that we must consider, including sensor later maintenance and operation difficulty. So I think it's important to share my point of view with you.

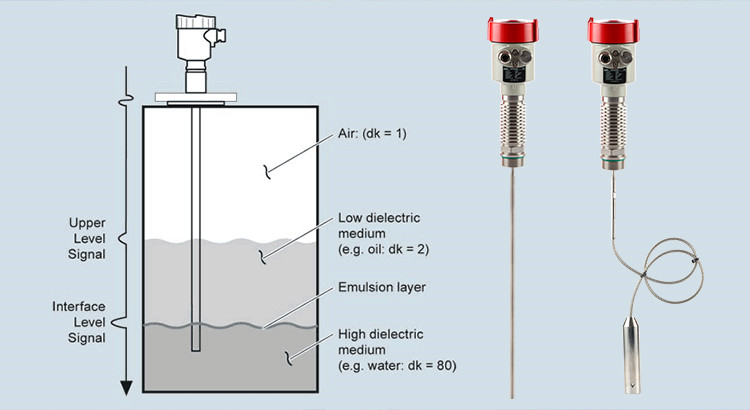

In most cases, interface level transmitters are divided into Long Range Radar Liquid Level Sensors and High Temperature Radar Distance Level Meters. That's what we call the rod type and the cable type. Based on time domain reflection principle (TDR), the electromagnetic wave of the interface level transmitter propagates in two forms. Once it encounters the measured medium, part of it's pulse will be reflected to form an echo and return to the transmitter along the same path. Finally, the height of the liquid level of the industrial tank can be obtained through the propagation time.

The purpose of selecting the interface level transmitter

Usually we will discuss based on the advantages of interface level transmitter. First, it is used for continuous level measurement of liquids, particles and slurry in any industrial tank, and is not affected by medium, temperature, inert gas and steam, dust, foam and other factors. Whether we use metallic tanks, non-metallic tanks and any chemical tank have a good effect. Second, if it is a food-grade medium, we will try to avoid using contact sensors to complete the measurement. Third, different types of interface level transmitters are used according to the size of the industrial tank range. The rod type is usually used within 15 meters, and the cable type is usually used within 60 meters. In a word, whether considering the medium or the measuring environment, interface level transmitter is the most correct choice for industrial tank level monitoring.