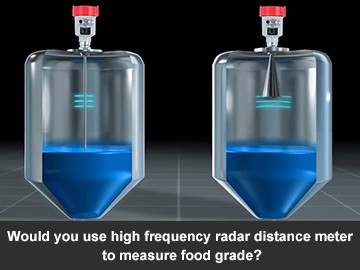

Would you use high frequency radar distance meter to measure food grade?

With the increasing frequency of high frequency radar distance meter used for industrial medium measurement, there are new solutions for food level measurement. Using the radar meter based on the time-domain reflection principle, it can transmit the measurement data through the radar pulse wave, so as not to contaminate the medium reaching the food level. Under the premise of ensuring hygiene, the most needed result is to obtain efficient measurement data.

The advantages and disadvantages of high frequency radar distance meter

The reason why 26G High Frequency Radar Distance Meter attracts much attention depends on it's inherent characteristics. Because it is solid, no mechanical parts drift or wear away, and more importantly, it is unaffected by changes in pressure, steam, temperature, viscosity and density. Just as the price of computers has fallen so far that everyone can own them. As a result, it is now possible to install the latest HF radar level sensors in all factories and manufacturing plants. In food production, it's internal structure is usually prominent, but space is very valuable. Another advantage is that it can be mounted closer to the side of the container and higher nozzles. Second, it can also be used in higher containers. It's disadvantage is that with the increase of the measurement range, it's blind spot will become larger. Therefore, we should avoid using radar level sensors above 50 meters.

You might think that high frequency radar distance meters are expensive and expensive to maintain. But there is no denying that it is the best choice for food grade level measurement.