Radar Level Transmitters: Troubleshooting, Common Faults and Solutions

76-81GHz radar level gauge is a level measurement equipment using high-frequency radar technology, with features of high precision and applicability of complex environments. However, we may also face some common faults, and generally we can troubleshoot by checking the following:

1.Whether the power supply is normal

If we find that the radar level gauge changes very slowly or does not change at all after the liquid level rises to a certain value on the production site, first of all, it is necessary to check whether the fuse of the equipment is burned out. If there is no current output, it can basically be judged that there is a problem with the instrument. Replace or repair as necessary.

2.Whether the communication equipment is normal

Once the communication equipment is found abnormal, we can install radar debugging software to read the configuration data and monitor the status of the radar sensor, mainly to check whether the radar sensor can accurately judge the difference between the reflected echo and the false echo, and whether the intensity of the reflected wave reaches the predetermined standard. If there is no problem with the above tests, other electronic components need to be checked. If it is judged that the communication unit is damaged, the components need to be replaced as appropriate.

3.Whether the displayed value is accurate

Inaccurate value is a common problem with radar level gauges. The cause may be that the initial setting is not proper, or because the plug-in connection of the display module is incorrect. Once it is found that the displayed value is not visible, we should check the initial setting of the radar level gauge and check whether the connection of the display module plug-in is normal. Otherwise, further check whether the output current of the radar is normal, and replace the electronic module in time.

4.Measured value fluctuations

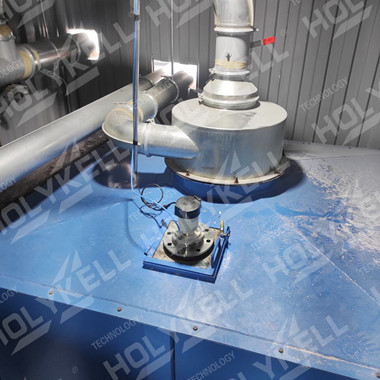

In the tank, due to the violent fluctuation of the surface of the stirring medium, or the enhancement of the temporary interference echo in the tank due to feeding, the measured value fluctuates. In addition to improving application parameters, activating near-field suppression, and increasing output damping, we should also check the installation location of the meter, or consider installing a larger antenna.

5.Whether the system displays error

When the system displays an error message, it is generally possible that the power supply was cut off before the end of data storage. At this time, we need to verify, reset and re-calibrate. If the alarm is still issued, the electronic module of the radar level gauge needs to be replaced.

6.Diffuse reflection

Diffuse reflection refers to the phenomenon that light projected on a rough surface is reflected in all directions. When the liquid level is low or there is no liquid level, the biggest reason may be that there are brackets and pipes at the bottom of the container, or steam is generated during the process, which forms diffuse reflection on the radar wave. At this time, we can restart it for automatic recovery after the liquid level is normal. The diffuse reflection caused by steam will automatically recover after the temperature is normal.

FAQs

Below we also list some FAQs by customers during use of radar level transmitters and our suggestions.

1.Q:How to deal with the ladder, steps and stirring inside the tank?

A: When installing the radar level sensor, keep it away from obstacles such as ladders and steps as far as possible. If it is unavoidable, we can do false echo leaning. Note to set the distance before the learning.

2.Q: There are turbulence, vortex, thick and thick foam on the surface of the liquid, resulting in wave loss or weak signal, how to deal with it?

A:Mode can be modified to improve radar measurement output stability and signal value.

3.Q:How to deal with the medium with low dielectric constant?

A: When measuring some media with low dielectric constant, such as cement powder, gasoline, organic solvents… we may face wave loss or weak signal. We can modify the mode to improve the radar measurement output stability and signal value.

4.Q:How to deal with the fog in the tank?

A:If the fog is thick, we can choose a large-range electronic module to improve the signal.

5.Q:How to deal with the dust in the tank?

A:When measuring strong dust conditions, such as cement powder, we can choose to install a purging device, but note to prevent the lens surface from being blocked.

6.Q:How to deal with antenna contamination and crystallization?

A:In the absence of an air source, we can only clean the radar lens surface regularly. After the power is cut off, wear appropriate protective equipment, remove the radar and put it down at an angle, wipe off the dirt or crystals with a rag, do not let the antenna be bent and damaged, handle it with care. Or we can also install a purge device to solve this.

7.Q:How to deal with the condensed water or freezing of radar level gauge antenna in winter?

A: In addition to regular inspection and cleaning, it is recommended to install insulation and trace heating devices outside the radar gauge to keep the temperature near the tank mouth basically constant.