Fuel Level Monitoring at Gas Station Using Automatic Tank Gauge (ATG) System

What is an ATG System?

An Automatic Tank Gauge (ATG) system is a monitoring system designed to track various parameters within underground or aboveground storage tanks, particularly at gas stations. This includes detecting fuel levels, water levels, liquid temperature, volume, and space.

Why Gas Stations Need ATG Monitoring Systems?

ATG systems play a crucial role in ensuring accurate tracking of product levels and compliance with national regulations. By eliminating manual measurements and monthly inventory calculations, ATGs provide precise data and reports on product delivered and dispensed.

How Does the ATG System Work?

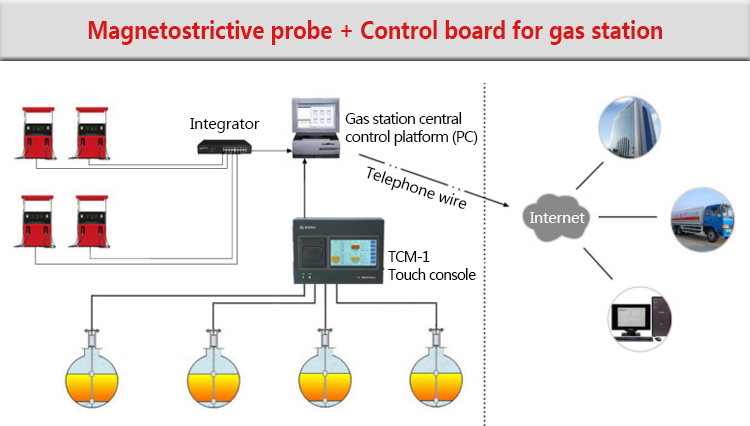

The ATG system consists of a magnetostrictive probe and a smart console.

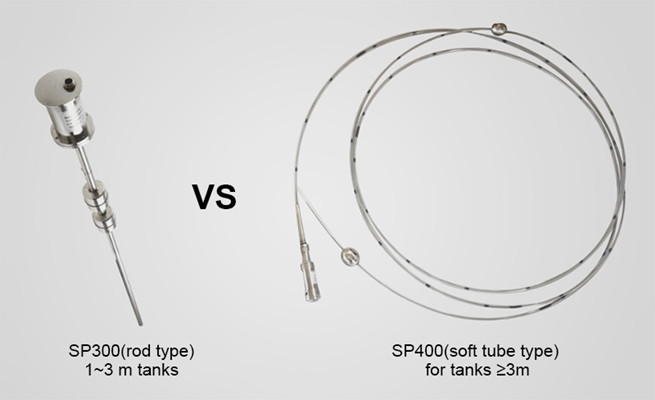

The magnetostrictive probe is installed in the opening at the tank tops, featuring two floats that measure fuel and water levels. A pulse is sent to the float and is measured back at the head of the probe.

The SP300 model is ideal for tanks ranging from 1 to 3 meters, employing a rod-type design, while the SP400 model suits tanks taller than 3 meters with a soft tube configuration.

Key Features of Magnetostrictive Level Sensor SP300/SP400 Series:

1. Safety

Intrinsically safe EXiaIIBT4Ga certification by PCEC.

2. Accuracy

High-speed digital design, achieving level measurement accuracy up to ±0.3mm.

3. Stability

Digital data collection, robust anti-interference, and corrosion resistance to oil, acid, alkali, and aging.

4. High Speed

Single tank inspection speed less than 1 second.

The measured data from magnetostrictive level gauges can be conveniently displayed on the console, PC, and mobile applications.

Key Features of TCM-1 Touch Control Console

1.Monitor 1 to 12 oil tanks, supporting automatic and manual oil unloading, and oil tank leak detection.

2.Real-time display of oil level, water level, temperature, tank inventory, and empty volume.

3.Dynamic graphical representation of oil and water level changes on a 7-inch color touch screen.

4.Alarms for oil level, high water level, and upper and lower oil temperature.

5.Two RS-232 communication ports for connecting central control units of different brands.

6.Recording and query functions.

7.Optional functions, including printing, data upload for remote access, submersible pump control to prevent spills, and connection of flow meters to display oil unloading.

Holykell has helped gas stations all over the world for safe and accurate fuel level monitoring for many years. You can contact Holykell engineering team for more technical data and solutions.

Related Posts

Magnetostrictive Level Transmitter for Gas Station

How Does a Magnetostrictive Level Probe Work