Mass Flowmeter VS Oval Gear Flowmeter: Which One to Measure Palm Oil?

In the palm oil industry, accurate flow measurement plays a critical role in production control, trade settlement, and quality assurance. Among so many types of flow meters, mass Coriolis flow meters and oval gear flow meters are two of the most commonly flow meter types. Both have their advantages and limitations, especially when it comes to handling the unique characteristics of palm oil, such as high viscosity, tendency to solidify, and sensitivity to temperature.

Working Principles: Mass vs. Volume

Mass Flow Meters

Mass flowmeters, particularly Coriolis flow meters, measure the mass of fluid directly by utilizing the Coriolis effect. As palm oil flows through vibrating tubes, the inertial force causes a phase shift. The mass flowmeter detects this shift and calculates the mass flow rate, and often also outputs density and temperature simultaneously. No additional instruments are required for compensation. It can also measure the medium volume, temperature.

Oval Gear Flow Meters

Oval gear meters are a type of positive displacement flow meter. Fluid passes through the meter and rotates a pair of oval-shaped gears. Each rotation moves a known volume of palm oil. To obtain mass flow, users need to apply density compensation, which requires either a separate density meter or an estimation based on stable process conditions.

Accuracy and Measurement Reliability

Mass Flow Meters: with an accuracy up to 0.1%, Coriolis meters are highly precise, and measurement not affected by changes in palm oil temperature or density. This makes them ideal for custody transfer, blending operations, and any process requiring tight control.

Oval Gear Flow Meters: Oval gear meters also offer high volume flow accuracy 0.5% under stable conditions. However, if palm oil’s composition or temperature fluctuates , which can change its density or viscosity, it may introduce errors unless compensated properly.

Fluid Compatibility and Performance

Mass Flow Meters: not sensitive to viscosity, suitable for palm oil of different viscosity, including both molten palm oil at high temperatures and semi-solidified oil near its freezing point (around 35°C). Since there are no moving parts, they are also less prone to blockage or wear due to impurities.

Oval Gear Flow Meters: Best suited for medium to high viscosity fluids, they work well with palm oil at room temperature. However, very thick or low-temperature palm oil can slow gear rotation or cause clogging. Besides, they are more sensitive to solid particles or impurities, so filtration is often required otherwise the accuracy will be reduced.

Pressure Drop and Flow Resistance

Mass Flow Meters: a higher pressure drop due to their internal vibrating tube structure. This may affect flow efficiency for very viscous palm oil unless the system is properly designed.

Oval Gear Flow Meters: generally a lower pressure drop, although gear resistance increases with viscosity. This makes them more energy-efficient in low-to-medium viscosity applications.

Maintenance and Cost Considerations

Mass Flow Meters: typically more expensive upfront, but offer low long-term maintenance. The absence of mechanical parts means fewer breakdowns and high reliability over time. They’re particularly cost-effective in high-value or critical process lines.

Oval Gear Flow Meters: With lower initial cost, they are a popular choice in budget-limited projects and stable working condition applications. However, the moving parts require periodic cleaning and maintenance, and worn gears may reduce long-term accuracy.

Typical Applications

Mass Flow Meters are ideal for:

Trade metering and custody transfer of palm oil

Accurate blending or recipe control in food and chemical processing

Applications requiring simultaneous density and temperature monitoring

Oval Gear Flow Meters are preferred for:

Batch control or filling systems in palm oil logistics

Storage transfer and pipeline measurement

Processes with stable viscosity and clean media

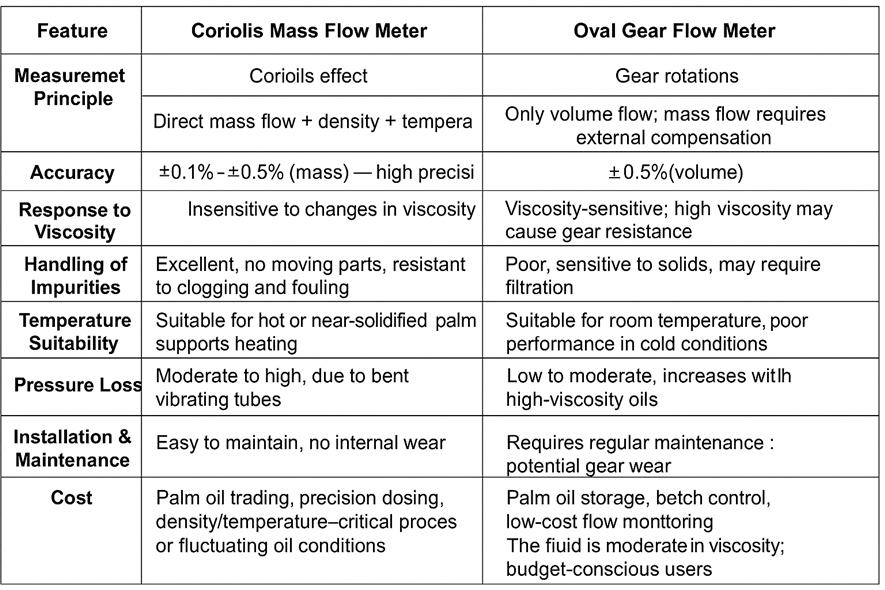

Comparison Table Between Mass Flowmeter and Oval Gear Flowmeter

Note: Since palm oil tends to solidify below 35°C, both types of meters should be installed with heat tracing or insulation to prevent clogging. Coriolis meters are generally more resistant to solidification-related issues due to their design.

Conclusion

There is no one-size-fits-all device. Choosing a mass flow meter or an oval gear flow meter depends on your budget, technologies and accuracy requirements. Understanding these key differences ensures you choose the right flow solution for your palm oil application, ensuring both operational efficiency and measurement integrity.